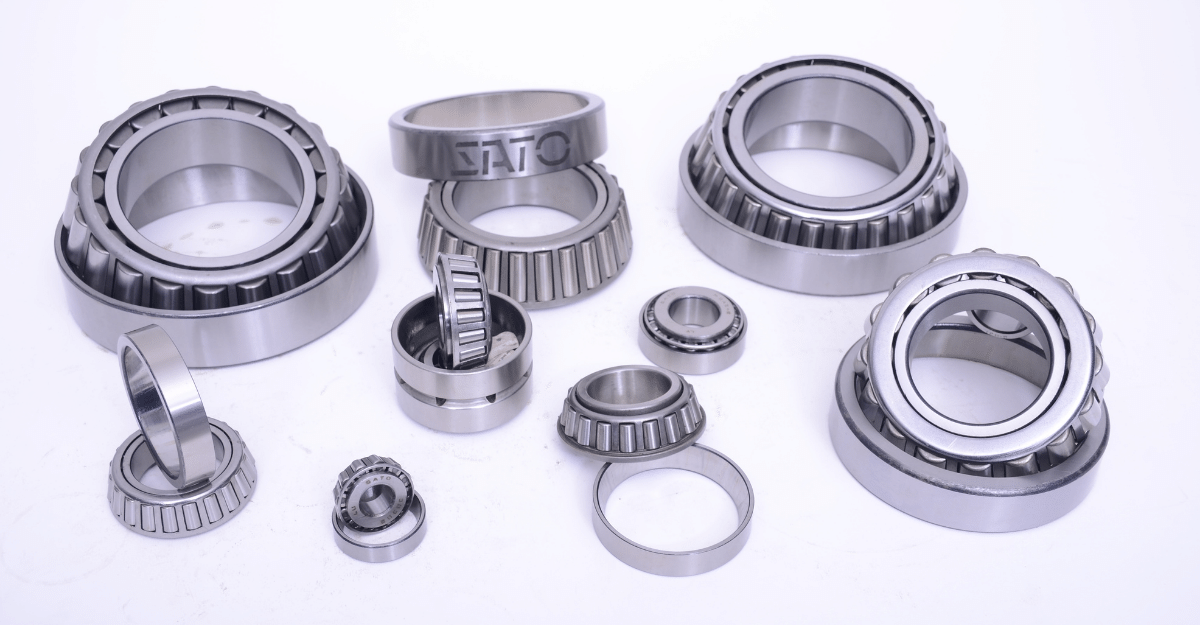

Tapered roller bearing are created such that their conelike rollers and raceways are to ensure that all component of the roller and raceways cones fulfill at a common peak on the bearing axis. The rollers are led by the contact between the large end of the roller and also the rib on the internal ring (cone). This building and construction offers a high ability for radial loads, axial loads and incorporated lots. The larger the contact angle, the better the loading capacity becomes. When a pure radial is positioned on the bearing, an induced lots in the axial instructions is also created. So these bearings are typically utilized in sets opposing each other. Correct running clearance or preload can be gotten by changing the distance of both bearings against one another. Considering that the inner (cone)as well as outer (Mug) rings are separable, each ring can be installed separately, permitting both rings to use tight suitable methods, if desired.

Both metric as well as inch systems are standardized by bearing collection and also both systems are commonly used. The statistics system’s defined in ISO (ISO 355) and JIS B 1512 and also the inch system (consisting of J collection) is standard in AFBMA criterion.

Press Steel cages are normally made use of in these bearings, nevertheless large-size bearings make use of machined or pin types cages. Smaller sized dimensions in some cases utilize plastic cages relying on the application.

SUBUNITS: Conical roller bearings can be taken apart into subunit, this is the internal ring with rollers (cone) and the external rings (mug). The subunit measurements are standard on ISO as well as AFBMA requirement, the linked subunits give interchangeability within each dimensional criterion. In addition, since high accuracy grade bearings are not interchangeable these bearings should be assembling subunits with the identical manufacturing number.

Pertaining to the single row tapered roller bearings explained in the dimensional table, the measurements for these subunits are standardized for both statistics as well as inch systems (including J- series) unless otherwise noted.

ALLOWABLE MISALIGNMENT: By suitably setting the call condition of the rollers with the raceway ring, not just is side loading avoided. The allowable imbalance in between the inner as well as external rings caused by installing mistake can be allowed. The allowed imbalance for tapered roller bearing has to do with 0.0005 radian (0.,15′) for single row or back to back plan is required by the bearing, please speak with ARB.